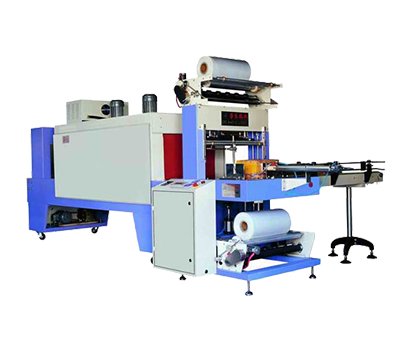

Carton Over Wrap Machine

Description

Description

Renuka Automation accompanied with advance manufacturing unit suppliers complete range of candy flow lollipop wrapping machines in Mumbai, India. Our manufactured wrapping machinery are well known for their compact design, sturdy construction & reliability that provide best suitability of the customers. We manufacturer all types of wrapping machines under the guidance of our highly skilled technical experts by making utilization of best quality raw materials and different component. Our experts guarantee that these machines have high rigidity and longer useful life by performing various tests utilizing latest equipment and technology. Hence we are notable flow wrapping machine Manufacturer Company in India based in Thane.

Infeed section

The products are fed to the infeed conveyor of the machine . As the products collate at pusher area, the line stopper stops the product and the line sensor get actuated. Once the system assures enough accumulation of products, signaled by the product accumulation sensor, the gate valve actuates and holds the upcoming products and clear the infeed gate. After a delay the pusher pushes the collation through the curtain of film to make the sleeve.

Sealing and Film Feeding Section

The Sleeve Wrapper uses two rolls of single wound. The film unwinding is by motorised with dancing bar arrangement.

The sealing system consists of a Special sealing system suitable for P.E.films. Once the product reaches sealing zone, the top hold down plate will come down and holds the product and then the vertical sealing arm will get actuated to seal the film and completes the wrapping operation. Once the seal is made, the sealing arm get retracts. The product is pushed into the infeed conveyor of the Shrink Tunnel by the driven outfeed conveyor.

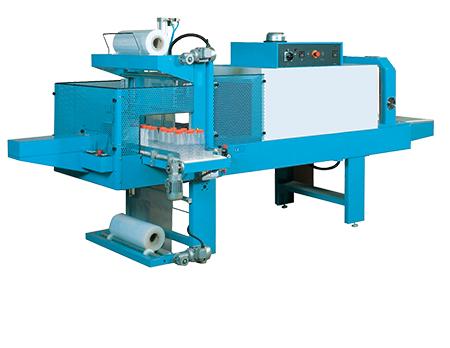

Shrink Tunnel

The shrink tunnel is used to circulate hot air around the pack as it moves on the conveyor. The air from inside of the tunnel is sucked and blown on the heater (finned type). This re-circulated air comes on the pack from all sides, top bottom thereby giving a uniform shrink to the pack. During the first quarter of the tunnel, the film gets hot air only from the bottom and then from all sides. This helps in shrinking PE film well and helps to pull the seal to bottom of unit. Once the unit moves out of the hot chamber, then cool air is thrown on the unit to achieve a tight cling on the unit and it cools the unit.

Copyright (c) 2024 Renuka Packaging Machines & Automations